sales@kanaksteeleng.com

sales@kanaksteeleng.com  +91 9920755510

+91 9920755510

sales@kanaksteeleng.com

sales@kanaksteeleng.com  +91 9920755510

+91 9920755510

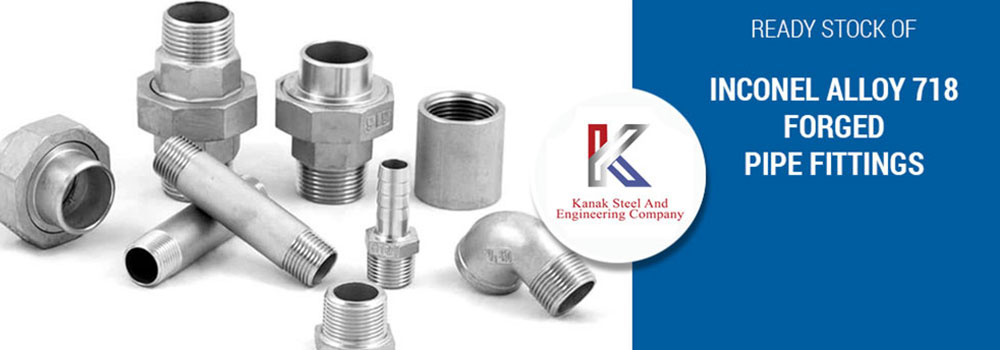

Suppliers and Manufacturer of Inconel 718 Forged Threaded Fittings & Forged Socket Weld Fittings, which has numerous exquisite attributes to offer like non corrosive, smooth installation, correct dimensions, and so on. Inconel 718 Forged Threaded Coupling Fittings are synthetic with exquisite precision the use of surest exceptional cloth in adherence to worldwide exceptional standards. Inconel UNS N07718 Forged Socket Weld Coupling Fittings additionally has a few different exquisite capabilities to provide inclusive of robust creation, dimensional accuracy, corrosion resistance, lengthy provider lifestyles and more. We are a comprehensive inventory of Inconel 718 Forged Fittings, socket weld & threaded fittings in a large variety of types, sizes, schedules, and pressures. Inconel 718 Forged Socket Weld Tee is age hardenable and may be welded in fully aged condition, along with having excellent oxidation resistance up to 1800 degrees F (980 degrees C). It additionally gives excessive strength, durability, thermal resistance, chemical resistance, terrific finish, correct dimension, hard-wearing, smooth to put in and more.

The Inconel 718 Forged Threaded Fittings are hardened with the help of the highly effective annealing process and this allows effective welding at all temperatures. Inconel DIN 2.4668 Forged Threaded Union Fittings is likewise utilized in Mining Industries, Space & Defence Industries, Gym And Health Care, Highway / Roadways Signage’s And Sign Boards. Inconel 718 Forged Socket Weld Fittings is another type of fitting in which the forging process is used so as to provide more strength, high corrosion resistance and greater reliability. Some of the fittings we produce for Inconel 718 Forged Fittings include Inconel 718 Forged Equal and Unequal Tees that are flawlessly designed according to latest engineering and designing standards. Inconel 718 Socket Weld Fittings are mostly used in the piping systems where the diameter of the pipe is less than NPS 2. Inconel 718 Forged Socket Weld Union Fittings has numerous exquisite attributes to offer like smooth handling, compact design, much less fee maintenance, harm resistance, faultless performance, lightweight, and more. It has a few exquisite capabilities to provide inclusive of rust proof, leak proof, dimensional accuracy, corrosion resistance, etc.

| Specifications | ASTM B564/ ASME SB564 |

|---|---|

| Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Types | Socketweld Fittings, Screwed-Threaded Fittings |

| Pressure Rating | Threaded End-2000lb/ 3000lb/ 6000lbs Socket-weld End-3000/ 6000/ 9000lbs |

| Thread | NPT, BSPT, BSPP |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, and Unions, Forged Pipe Fittings, Socket Weld & Threaded, Equal Tees & Reducing Tees, 90° & 45° Elbows, Plugs |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

| STANDARD | UNS | WERKSTOFF NR. |

| Inconel 718 | N07718 | 2.4668 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi –1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |